Extremely sophisticated in tech and function

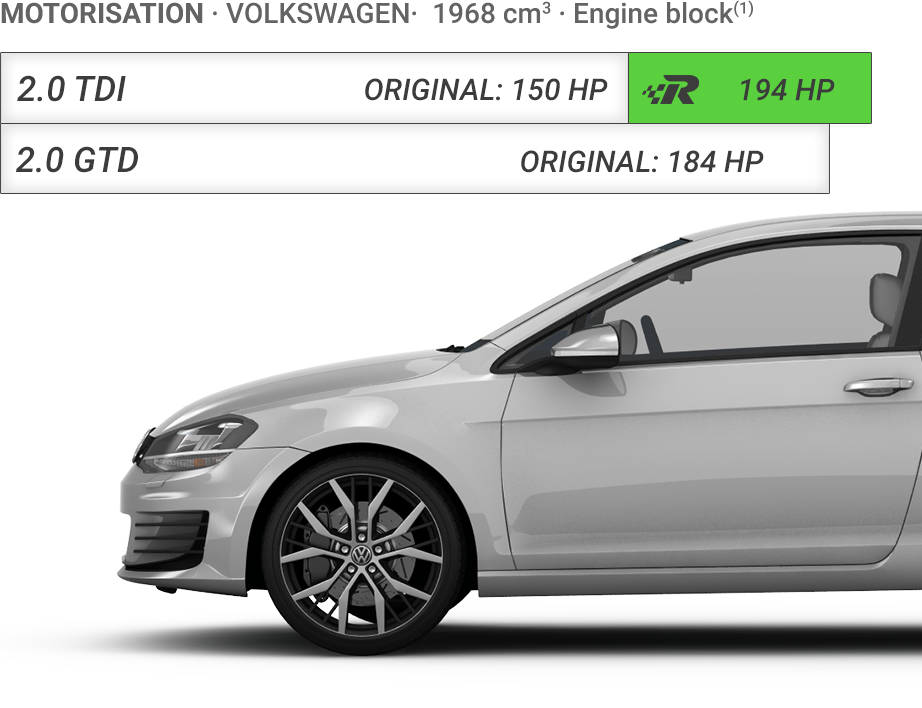

(1) The motorizations shown here are all based on the same engine block.

Nowadays, car manufacturers build just a few base engines and differentiate the power output via the electronic control unit: the same hardware, but with different software.

We at RaceChip are absolute experts in car tuning software. The data from the ECU is read by our tuning software and individually optimized. This way, you can enjoy a performance upgrade of up to 30%.

We use only the available power reserves and stay within tolerances, which are important to maintain your engine’s long-term endurance. Existing engine protection systems remain fully intact.

Simple. Tested. Safe. RaceChip.

The RaceChip Plug & Drive system: you can install all of our car tuning software modules easily and without specialist knowledge or tools. You only need 10-15 minutes. See for yourself the installation steps for an exemplary car model.

You’ll receive car model-specific installation instructions with each RaceChip, and there are installation videos for many car models in our database.

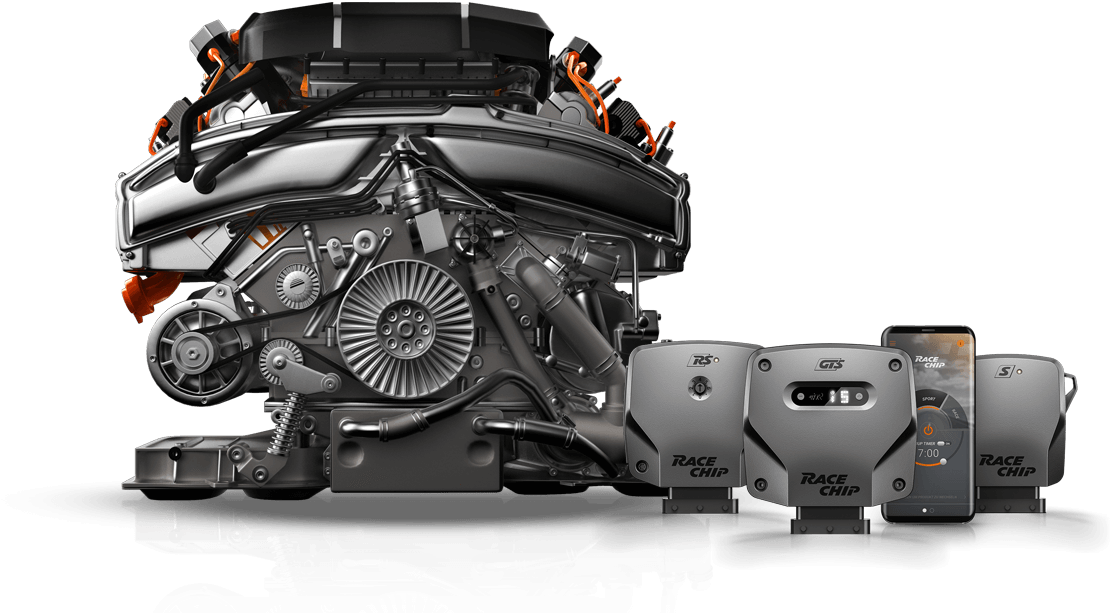

Modern, turbo-charged diesel engines use sensors to collect, monitor and transmit important information to the electronic control unit (ECU). Then, based on the data measurements, the ECU sends commands to various engine components like the fuel injection system.

This is precisely where RaceChip common rail tuning comes into play. Our supplementary control unit directly reads the information from common rail pressure and turbo-charge pressure sensors like fuel injection pressure, fuel injection quantity, injection frequency and turbo-charge pressure. The signals are optimised in real time by our optimisation software and then transmitted to your vehicle’s ECU. At the same time, the ECU adjusts all of the other relevant parameters in the engine to the new, optimised values. The decisive advantage is that the manufacturer’s ECU always has full control over all of the engine control parameters.

Signal optimisation leads to an increase in the fuel injection quantity, injection pressure and – to a slight extent – the turbo-charge pressure. This increases the fuel compression along with the energy released through combustion. The increased fuel injection quantity further supports this effect.

The engine’s overall efficiency factor and power potential increases significantly. For you, this means more power and a whole new level of driving experience.

Modern Otto and petrol engines use sensors to collect and monitor a variety of parameters during operation. The data flows to an ECU and is processed there. Fuel injection quantity, boost pressure and air mass are the decisive factors in RaceChip performance improvement.

To improve the performance of super-charged petrol direct injection engines (regardless whether with turbo-chargers or compressors), our chiptuning module must read and revise the relevant parameters. We use data from the boost pressure sensor, the intake manifold pressure sensor and air mass sensor. The chiptuning software module processes in real time and then transmits the optimised data to the corresponding control sensors in your vehicle. The result is a considerable power boost you can feel – by increasing the boost pressure, adjusting the fuel injection angle, and slightly increasing the fuel injection quantity.

To increase the boost pressure, the turbine RPM is increased within a range defined by us, which increases your engines efficiency level. This provides more air for the engine, which allows the ignition timing to be adjusted more precisely and makes combustion in the cylinder more effective. Because more air is available for combustion, the fuel injection quantity must be increased somewhat for the ideal fuel-air mix in the combustion chamber.

More power and higher efficiency levels for your engine are the results of this precisely fine-tuned interplay between many factors. In doing so, all of the relevant engine data is continually collected and tested for plausibility in real time.

Because the integrated safety systems in your engine always maintain control with RaceChip car tuning software, they can kick in if variations ever occur. This ensures that you and your engine are always on the safe side.

In general, two approaches to electronic performance tuning can be distinguished: (1) Performance tuning by directly accessing and reprogramming the engine control unit (ECU), also called on-board diagnostics (OBD) tuning, and (2) optimization with auxiliary control devices also referred to as performance chips, tuning chips, tuning boxes, piggybacks, power chips or power boxes.

Performance improvements are achieved by optimizing the electronic signals. This is done via the OBD2 port (also used to read the engine’s error memory) or by breaking into the ECU and adjusting or overwriting the manufacturer’s software itself, usually referred to as remapping or ECU flashing. In other words, it actively intrudes into the manufacturer’s configuration. This remapping technology can be used in all engines with electronic engine controls.

Performance improvements are achieved by optimizing the engine’s electronic control signals. The auxiliary control device (a kind of mini-computer) is placed between the engine controls and sensors, which enables performance upgrades of up to 30% using RaceChip’s tuning software. This engine tuning technology can be used in all modern diesel and turbo-charged petrol engines.